Stryüm Interlocking Aluminium

Cladding System

| Material | Prefinished solid aluminium cladding panel |

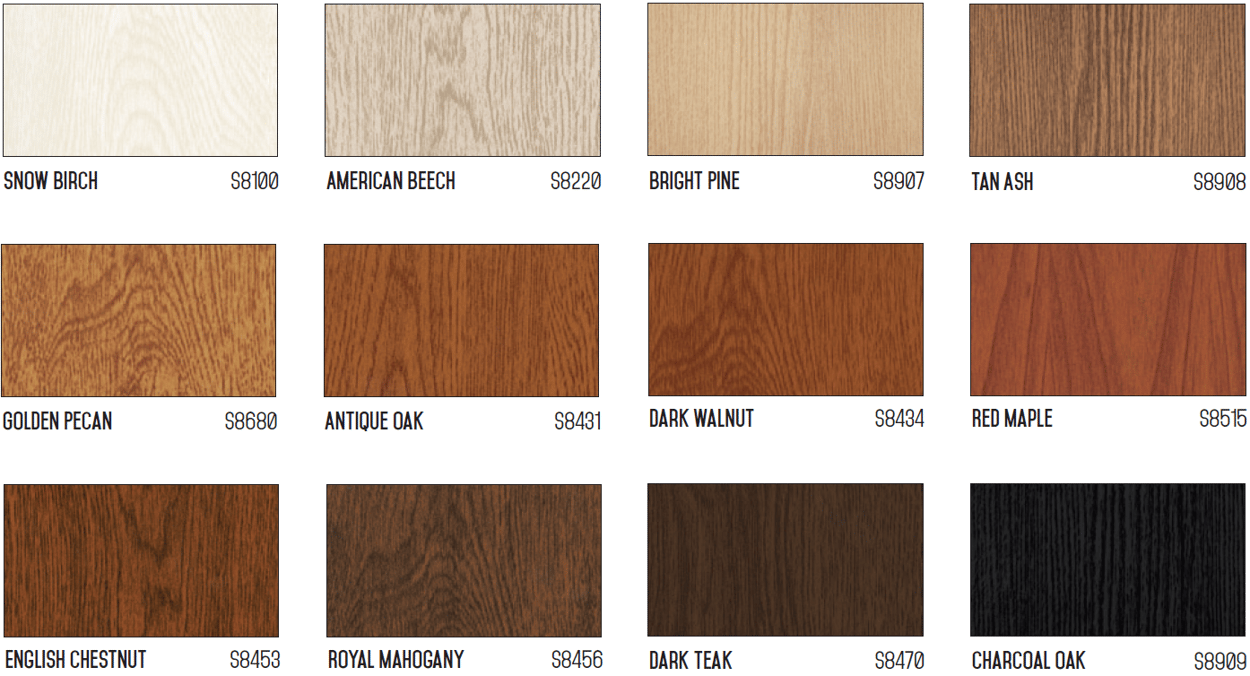

| Finish | Unlimited powder coat finishes, innovative textured woodgrain finishes and authentic anodised finishes. |

| Fixing System | Interlocking panels with concealed fixings for express installation 15-year standard warranty, subject to terms and conditions |

| Warranty | 15-year standard warranty, subject to terms and conditions |

| Application | Type A, B and C constructions where non-combustible materials are required, such as mixed-use developments, residential construction, and large-scale government infrastructure projects like hospitals. |

Combining limitless design flexibility and an unmatched level of compliance testing, Stryüm is the perfect metal cladding choice for designers and builders.

Sharing its DNA with Fairview Vitraloc metal cladding, Stryüm is a non-combustible, contemporary solid aluminium cladding system available in various striking profiles.

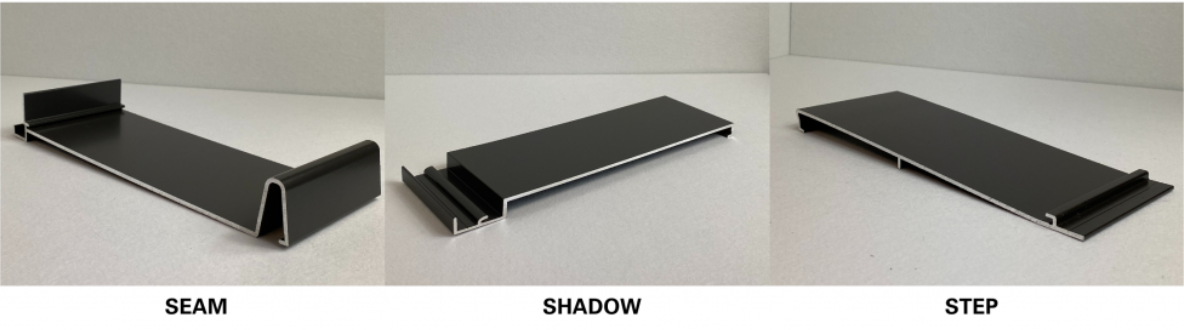

Boasting the biggest range of premium interlocking panels with concealed fixings on the market, you can install these aluminium cladding panels either horizontally or vertically for maximum flexibility and express installation, creating a multisensory design experience.

This 100% Australian-made and manufactured solid aluminium panel system will deliver high standards in quality, longevity and functionality to your external façade.

View the new range of sleek styles with Ezy HD2’s superior powder-on-powder finishes for an earthy woodgrain design, unlimited powder coat finishes, or an authentic anodised finish for a project that epitomises simple modernity.

Ideal for residential constructions, mixed-use developments, and large-scale government builds, this non-combustible, prefinished aluminium rainscreen cladding is installed on a ventilated substructure to allow for airflow and circulation behind the panels. This application allows the building envelope to breathe, bringing outstanding thermal performance and energy efficiency.

Benefits of Stryüm’s new range of aluminium wall cladding panels

As one of Fairview’s premier horizontal or vertical cladding panel products, Stryüm's interlocking rainscreen façade system is an unmatched choice within the architectural and construction industry.

- Superior quality products

- Unmatched durability and longevity

- Versatile

- 100% customisable, flexible commercial & residential aluminium cladding

- Perfect for use in A, B and C developments

- New range of Ezy HD2 powder-on-powder superior finishes

- Anodised or wood grain effect composite cladding

- Non-combustible aluminium cladding in accordance with the NCC clause C2D10(6)(e) and tested to AS1530.1 AND AS1530.3

- Tested to AS4284 Australian standards, ensuring your project will remain watertight for years to come

- Australian-made and manufactured

- Recyclable

- Versatile and flexible

- Durable

- Modern

- Lightweight

- Pending CodeMark Certification

- Outstanding thermal performance

- Fairview’s exceptional service and support, from design to installation

Stryüm is the ideal premium aluminium façade system for construction and design professionals. Contact us today for a free product sample to inspire your project!

Fairview Projects Using Stryüm Commercial Cladding Systems

Fairview Stryüm Product Documents

Frequently Asked Questions

What is Stryüm cladding?

Stryüm is one of Fairview’s premium external aluminium cladding systems featuring interlocking panels, subtle fixings, and a range of stunning profiles.

How long does the powder on powder woodgrain finish last?

High-end woodgrain or anodised aluminium cladding panels such as these are expected to last 25 years. We provide a product warranty of minimum 15 years.